If you are looking to learn more about the differences between chamfer and bevel, then you have come to the right place. Here you will learn about the uses of chamfers and bevels, as well as how to use them safely.

Fillet Vs Chamfer

If you are looking to make a design using machined parts, you might be wondering which process to use – fillet or chamfer. While both are used to smooth out an edge, they work differently. The choice between chamfer and fillet is an important one, and can affect the overall performance of your design.

Both chamfer and fillet are effective in creating smooth edges on your part. They also add aesthetics to the finished product. However, you should be careful not to choose the wrong machining method. This can reduce the durability of your design and may result in a poor print.

Fillets are more aesthetically pleasing, as they create rounded corners. However, they are not as durable or safe as chamfers. In addition, you have to choose the right whole shape. Otherwise, your design will be less functional and costly to manufacture. Chamfers, on the other hand, have a sloping edge. These corners, however, are not as sharp as those of a fillet.

Countersinks Vs Chamfers

There are two types of holes, chamfers and countersinks, and they serve very different functions. While both types overlap in functionality, there are some differences between them. The main difference is the gages required to measure each type. Unlike chamfers, countersinks are designed to plunge into an existing hole. This means that they are usually quite small and may only be a few millimeters in diameter. Usually, they are called out in blueprints. They are used in lathes, drills, and other milling machines.

A countersink is a device that is used to recess bolts, washers, and flat head screws. It is also used in some drill presses. Some of these tools are integrated into a step drill. There are three common types of tools for forming countersinks. These are coin dimpling, formed countersink, and modified radius dimpling. Depending on the material being used and the thickness of the sheet, a form countersink can be a good quality tool.

Safety Precautions For Chamfering Or Beveling

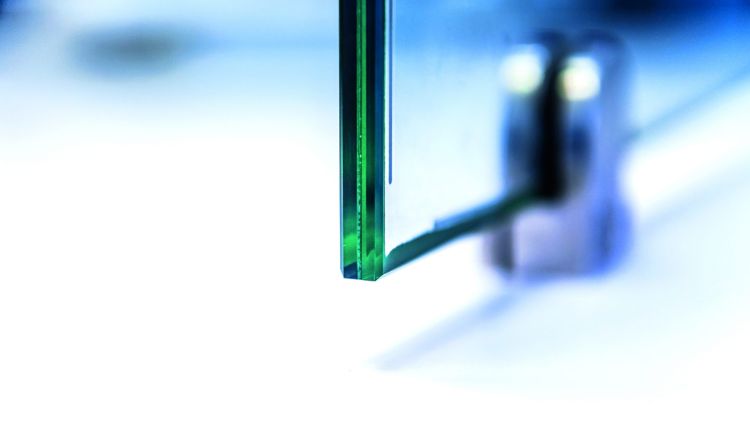

Chamfer vs bevel is the process of flattening the sharp edge of a part. It is a common procedure used in the manufacturing of various parts, and it can be easily carried out on wood, metal, and glass. To cut a chamfer, the operator needs to wear protective equipment. Moreover, the tool must be inspected and cleaned before use. The operator must also ensure that the debris shrouds work properly during the operation.

There are various methods for chamfering, but the user must decide which technique is the most economical and quickest. This will depend on the skill of the operator, the time available for the job, and the material being used. Rounded chamfers are generally used for aesthetic purposes. They provide a smooth edge that blends in with the adjacent faces, and reduces the stress concentration. In addition, they make the material safer for handling and are less likely to gouge the edges of holes.

Bevels, on the other hand, are intended for non-aesthetic purposes. In this case, they create a thinner, smoother, and more sharp edge. These surfaces are commonly found in countersinks, table tops, printed circuit boards, and nuts and bolts.

Common Uses Of Chamfers

Chamfer vs bevel are geometric shapes that provide an aesthetic and functional edge to a manufactured piece. These two edges are commonly used in a variety of applications. Choosing the right chamfer can ensure that your design is effective, while the wrong one can add unnecessary stress to the parts that it supports.

Chamfers are commonly used in industrial designs, but they are also used in carpentry and machining. They are used to eliminate sharp corners and to reduce material deformation. This makes a part easier to assemble. Using chamfers can also protect the edges of the parts from injury or damage.

Chamfers can also help make holes in a part easy to attach. Chamfers are usually cut at a 45-degree angle. In order to achieve this, a machinist will use a chamfering tool or cutter. The chamfer can be formed by filing, grinding or machining. It can also be produced by cutting the workpiece with a ground tool.

Last Word

However, a chamfer and a bevel are similar but there are some important differences. Chamfers are used to provide a smoother edge. Bevels are used to make objects wear resistant. Typically, chamfers are added to a metal workpiece for aesthetic or safety reasons. However, they can also be added for functionality. View herehttps://yijinsolution.com/titanium-vs-stainless-steel-what-is-the-difference/.